UN38.3 refers to paragraph 38.3 of Part 3 of the United Nations Manual of tests and standards for the transport of dangerous goods [formulated by the United Nations for the transport of dangerous goods, referred to as UN38.3. All airlines shall comply with the dangerous goods rules of the International Aviation Association Relevant provisions have made relevant detection provisions for mobile phone batteries, laptop batteries, interphone batteries, camera batteries, remote control toy batteries and other products applicable to rechargeable lithium batteries, including but not limited to those transported alone or with equipment. For products containing lithium batteries, the detection requirements are paragraph 38.3 of Part 3 of the United Nations Manual of tests and standards for the transport of dangerous goods, i.e. UN38.3

As lithium batteries are widely used in mobile communication equipment, electronic digital products, power products, medical and security fields, the transportation monitoring of lithium batteries is becoming more and more strict. Since lithium-containing batteries such as mobile phones and laptops are in constant danger during transportation, in order to effectively ensure the safety of battery air transportation and avoid unsafe events, during the collection and transportation of each type of battery at each airport, the battery needs to prove that it meets paragraph 38.3 (i.e. UN38.3) of Part 3 of the United Nations Manual of tests and standards for the transport of dangerous goods, and there is no UN38. 3. The qualified report cannot be receive

1. Various power secondary batteries (such as power vehicle battery, electric road vehicle battery, electric tool battery, hybrid vehicle battery, etc.);

2. Various mobile phone batteries (such as lithium ion battery, lithium polymer battery, etc.);

3. Various small secondary batteries (such as notebook computer battery, digital camera battery, camera battery, various cylindrical batteries, wireless communication battery, portable DVD battery, CD and MP3 player battery, etc.);

Lithium ion or lithium metal battery

Export to any country by air or sea

Un38 3. Test report: air transportation appraisal report; Marine appraisal report; 1.2m free fall

UN38.3

2-3 weeks

unwanted

1. Pi965 (lithium battery shipped separately)

Such as: lithium ion or lithium polymer cell and battery, mobile power supply, etc

1.PI965 ((lithium battery shipped separately)

Such as: lithium ion or lithium polymer cell and battery, mobile power supply, etc label:

2.PI966 (lithium battery and equipment package)

Such as mobile phones, cameras, etc

3.PI967 (lithium battery installed in the equipment)

Such as: tablet computer, Bluetooth audio, headset, etc

4.PI968 (lithium metal battery shipped separately)

5.PI969 (lithium metal battery and equipment package)

6.PI970 (ithium metal battery installed in the equipment)

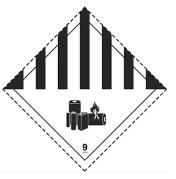

Lithium battery operation label

Size: 120*110mm or 100*100mm or 105*74mm

Put the lithium battery operation label on the outer box

Identification of class 9 dangerous goods

Minimum size: 100 * 100mm

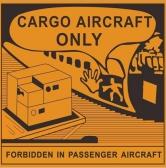

Shipping mark

Cargo label only

Size: 120 * 110mm

T.1height simulation test

Store the cell and battery in the environment with temperature of 20 + 5 ° C and atmospheric pressure of no more than 11.6kpa for no less than 6 hours

After the sample test, the open circuit voltage shall not be lower than 90% of the open circuit voltage before the test. This requirement is not applicable to batteries and cells that are fully discharged.

The sample (battery) shall be free of liquid leakage, exhaust, disassembly, rupture and ignition.

T.2thermal shock

Battery storage conditions are as follows:

The primary temperature cycle is 72 + 2 * C (6h) - 40 + 2 * C (6h)

The maximum interval of temperature conversion is 30min

repeat 10 cycles

At the end of the cycle, the battery is allowed to stand at 20 + 5 ° C for 24 hours

: the open circuit voltage after the sample test shall not be lower than 90% of the open circuit voltage before the test. This requirement is not applicable to the fully discharged battery and battery

The sample (battery) shall be free of liquid leakage, exhaust, disassembly, rupture and ignition.

T.3 Vibration test

. the electric cell and battery are firmly installed on the shaking table (table top)

The vibration is in the form of sine wave, increasing from 7Hz to 200Hz, and then reducing back to 7Hz as a cycle, - cycles of logarithmic forward transmission lasting 15 minutes.

The logarithmic sweep is: starting from 7 Hz, maintain the maximum acceleration of 1gn until the frequency is 18 Hz, then maintain the amplitude at 0.8 pen meter (total offset of 1.6 mm) and increase the frequency until the maximum acceleration reaches 8gn (the frequency is about 50 Hz), and maintain the maximum acceleration at 8gn until the frequency increases to 200 Hz.

One direction of vibration must be perpendicular to the polarity of the sample, from three mutually perpendicular directions for each cell Cycle up 12 times, 3 hours in each direction, a total of 9 hours.

After the sample test, the open circuit voltage shall not be lower than 90% of the open circuit voltage before the test. This requirement is not applicable to batteries and cells that are fully discharged.

The sample (battery) shall be free of liquid leakage, exhaust, disassembly, rupture and ignition.

T.4Impact test

Fix all accessory surfaces of each cell and battery sample with a stable bracket.

Each cell or battery is impacted with a half sine acceleration with a peak value of 150gn, and the pulse lasts for 6 seconds. Large batteries and large battery packs must withstand a half sine wave impact with a maximum acceleration of 50gn and a pulse duration of 11 seconds.

Each battery or battery pack shall be subjected to three shocks in the positive direction of three mutually perpendicular battery installation directions, followed by three shocks in the opposite direction, with a total of 18 shocks.

the open circuit voltage after the sample test shall not be lower than 90% of the open circuit voltage before the test. This requirement is not applicable to the fully discharged battery and battery Cell.

The sample (battery) shall be free of liquid leakage, exhaust, disassembly, rupture and ignition.

T.5external short circuit test

Keep the test ambient temperature stable at 57 + 4 ° C to make the surface temperature of the cell or battery sample reach 57 + 4 * C

Short circuit the positive and negative electrodes of the sample with a total resistance circuit less than 0.10, and maintain the temperature after the surface temperature of the sample is restored to 57 + 4 ° C

Short circuit condition for more than 1 hour.

The cell or battery must be further observed for 6 hours before reaching a conclusion.

cell or battery samples during the test and within 6 hours thereafter

-The surface temperature shall not exceed 170 ° C

- No disintegration, cracking and ignition.。

T.6impact test

Impact (for cylindrical batteries with a diameter of not less than 18 meters)

Place the cell or polymer cell used for the test sample on a flat and smooth plane upper

Place the cell or polymer cell used for the test sample on a flat and smooth plane

The longitudinal axis of the specimen subjected to impact shall be parallel to the flat surface and bent with a diameter of 15.8 + 0.1 mm placed horizontally in the center of the specimen The longitudinal axis of the surface is vertical. Each specimen is subjected to only one impact.

The maximum surface temperature of the cell or battery shall not exceed 170 ° C

Within 6 hours after the test, the cell and polymer cell shall be free from disassembly and ignition.

T.6 Extrusion test

Extrusion (for prismatic, bagged, coin / button batteries and cylindrical batteries less than 18 meters in diameter)

Squeeze the battery or component battery between two planes, and the extrusion force will gradually increase, and the speed at the first contact point will increas about 1.5 cm / s. The extrusion continues until one of the following three conditions occurs:

the applied force reaches 13 kn + 0.78 kn

-The battery voltage drops by at least 100 mV

-The deformation of the battery reaches more than 50% of the original thickness.

Prismatic or bagged batteries shall be pressed from the widest side. Button / coin batteries shall be pressed from their flat surfaces. The cylinder shall be pressed in a direction perpendicular to the longitudinal axis.

. the maximum surface temperature of the cell or battery shall not exceed 170 ° C

Within 6 hours after the test, the cell and polymer cell shall be free from disassembly and ignition.

T.7overcharge test

Charge the sample with 2 times the maximum continuous charging current recommended by the manufacturer

The minimum voltage for this test is:

If the charging voltage recommended by the manufacturer does not exceed 18V, the minimum charging voltage in this test shall be twice the maximum charging voltage calibrated by the manufacturer or the smaller of 22V.

If the charging voltage recommended by the manufacturer exceeds 18V, the minimum charging voltage in this test shall be 1.2 times of the maximum charging voltage calibrated by the manufacturer.

The test lasts for 24 hours at an ambient temperature of. 20 + 59C.

The test sample shall be free from disintegration and ignition during the test and within 7 days after the test.

T.8 forced discharge test

At the ambient temperature of. 20 + 5 ° C, connect a single cell to a 12V DC power supply for forced discharge. The initial current provided by this DC power supply to each cell is the maximum discharge current specified by the manufacturer.

The specified discharge current is obtained by a load of appropriate size and power connected in series on the test cell. The forced discharge time (hours) of each cell is the rated capacity divided by the initial current (AMPS).

The test sample shall be free from disintegration and ignition during the test and within 7 days after the test.

1.2m drop (after packaging)

Under the condition of 20 + 5 ° C, the packed lithium battery falls from 1200mm (the lowest point of the battery) to 18-20mm thick hardwood (the wood is paved on the cement floor).

The test sample will not catch fire or explode during and after the test.

Test qualification criteria

(1) In tests t.1 to T.6, there was no disassembly or fire.

(2) In tests t.1, t.2 and T.5, the effluent is not toxic, flammable or corrosive.

a. There is no exhaust or leakage through visual observation;

b. There is no exhaust or leakage that causes the weight loss to exceed that shown in table 38.3.4.7.1.

(3) In tests T.3 and T.6, the effluent is not toxic or corrosive.

a. There is no exhaust or leakage through visual observation;

b. There is no exhaust or leakage that causes the weight loss to exceed that shown in table 38.3.4.7.1.

(4) 1.2m drop from X, y, Z plus or minus six directions, one drop in each direction, no leakage, no disassembly, no combustion, no explosion, no damage.

Step 1:

Application

1. Determine customer information;

(1) Which city the customer's products are exported by air;

(2) Whether the customer's products are shipped separately or supporting other products.

2. Fill in UN38.3 Application form;

3. Provide battery specifications and other data.

Step 2

Quotation

Determine the test time and corresponding expenses according to the data provided.

Step 3:

Pay

After confirming the quotation, the applicant shall sign the filing application form and service agreement and pay the project fee.

Step 4:

Sample

Send samples to customers.

Step 5:

Test

Conduct un38 test on the applied products according to relevant test standards 3. Complete set of tests.

Step 6:

Report

The test passed and the report was completed.

Step 7

Certification

When the project is completed, the appraisal certificate will be issued.